Dil Değiştir :

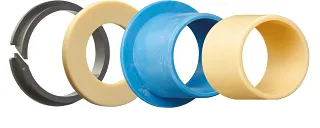

Bakım gerektirmeyen iglidur® plastikten yapılmış kaymalı yataklar

Kaymalı yataklar, örneğin şaft ve yatak arasında doğrudan teması önlemek için kullanılır, böylece aşınmazlar. Çoğu rulmanın düzgün çalışması için düzenli olarak yağlanması gerekir. iglidur kaymalı rulmanlar ek yağlayıcı gerektirmez, bu da onları bakım gerektirmeyen ve metal kaymalı rulmanlara göre uygun maliyetli bir alternatif haline getirir. Kaymalı rulman online mağazamızda çeşitli tiplerde ve 10.000'den fazla boyutta mevcuttur. igus tarafından özel olarak geliştirilen iglidur malzemeleri ile kaymalı yataklarımız için çeşitli endüstrilerde geniş bir uygulama yelpazesi gerçekleştirmek mümkündür. Yüksek sıcaklıklara, kimyasallara veya yüksek yüklere maruz kalabilirler ve gıda ile temas için uygundurlar.

Bir bakışta kaymalı yataklarımızın avantajları

iglidur kaymalı yatak online mağazasını şimdi deneyin

İglidur kaymalı yatak mağazası tüm katalog yelpazemizi içerir. Ayrıca, kullanıcıların özelleştirilmiş burçlar için fiyatları ve teslimat sürelerini birkaç saniye içinde hesaplamasına olanak tanır.

Ø3 - Ø195 mm şaft çapları için

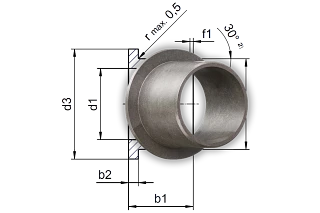

Flanşlı rulmanlar

Şaft çapları Ø3 - Ø195 mm için

Mağazaya ulaşabilirsiniz

Kovanlı yataklar

Şaft çapları Ø1,5 - Ø150 mm için

Mağazaya ulaşabilirsiniz

Baskı pulları

Eksenel yatak desteği için

Ø8 - Ø114mm

Kılavuz halkalar

Lineer kılavuzlar için

Ø4 - Ø80mm

Klipsli rulmanlar

Sac metal geçişler için

Ø8 - Ø25mm

İki delikli flanş yatakları

Vidalama için

Ø10 - Ø35mm

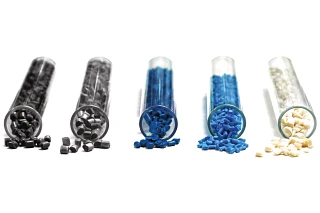

Kaymalı yatak malzemelerimiz

İglidur malzemelerimizle ilgili teknik bilgi ve veri sayfalarımıza genel bir bakışı burada bulabilir ve indirebilirsiniz.

iglidur malzemeleri hakkında daha fazla bilgi edinin

PTFE içermeyen ve PFAS testli kaymalı yatak burçları

PTFE ve PFAS'ın yasaklanmasına ilişkin mevcut tartışma nedeniyle, kaymalı yataklarımızla ilgili tüm önemli ayrıntıları burada derledik. Ayrıca PTFE içermeyen veya kritik veya sağlığa zararlı olduğu düşünülen PFAS için test edilmiş tüm iglidur malzemelerinin bir listesini bulacaksınız.

Özelleştirilmiş ürünler ve çizim parçaları

Kapsamlı standart ürün yelpazemize ek olarak, spesifikasyonlarınıza göre özel yapım ürünler de sunuyoruz. Aralarından seçim yapabileceğiniz çeşitli üretim süreçleri vardır, bu da sizin için her zaman en iyi teklifi seçebileceğimiz anlamına gelir.

Kaymalı yatak wiki

- İgus kaymalı yatak malzemelerinin kayma hızları nedir?

- İgus rulmanlar hangi sürtünme katsayısına sahiptir?

- Ve stick-slip etkisi nedir?

Bunlar ve diğer birçok soru burada yanıtlanıyor. Kaymalı yataklarımız ve malzemelerimiz hakkında bilmeniz gereken her şeyi öğrenin.

igus yeni kaymalı yatak ürünleri

Rulman teknolojisi alanındaki yeni ürünlerimizi keşfedin. Müşteri talepleri, bize sürekli olarak yeni ürünlerin geliştirilmesine yol açan zorluklar sunmaktadır. Amacımız, müşterilerimize her zaman en uygun maliyetli çözümü sunmak ve teknik ilerlemeyi mümkün kılmaktır.

Ürünlerimiz hakkında sıkça sorulan sorular

Daha fazla igus haberini kaçırmayın

-Hareketli plastik haberlerimiz ile igus ve ürünleri hakkında hiçbir haberi kaçırmayacaksınız. Bültenimiz sizi güncel tutacak: yeni ürünler, heyecan verici uygulamalar, güncel laboratuvar raporları ve çok daha fazlası.

Danışman

Sorularınızı kişisel olarak cevaplamaktan mutluluk duyacağım.

igus® Türkiye+90 444 63 51E-mail gönderin

Talepler ve Sevkiyatlar

Şahsen:

Pazartesi'den Cuma'ya sabah 9:00'dan akşam 6:00'a kadar.

Çevrimiçi:

24 saat