Dil Değiştir :

Enjeksiyon kalıplama makineleri için enerji besleme sistemleri ve rulmanlar

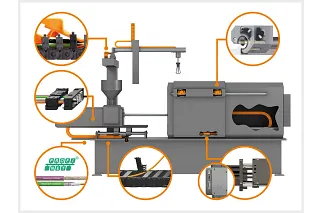

Makine yatağında, enjeksiyon ünitesinde, sıkıştırma ünitesinde ve taşımada: enerji zinciri sistemlerimiz, son derece esnek kablolarımız ve bakım gerektirmeyen yatak teknolojimiz, plastik enjeksiyon makinenizin tüm hareketli ünitelerinde uzun bir hizmet ömrü sağlar.

Chainflex® kablomuzun gerilim giderici damarlı, demet telli ve PVC veya TPE dış kılıflı özel tasarımı, sık hareket eden ve kısa döngü sürelerine sahip kapama ünitesi gibi son derece dinamik uygulamalar için idealdir. E-zincirimiz® kablo demetlerinin güvenli bir şekilde yönlendirilmesini sağlar. Tasarımları basit, hızlı kurulum ve kablo dostu bir iç kısım ile karakterize edilir - özellikle hidrolik hortumlar kullanılırken ilginçtir. Küçük montaj alanları için küçük boyutlara ek olarak, büyük desteklenmeyen uzunluklar ve ek yükler de mümkündür. Çok çeşitli malzemelerden üretilen rulman ürünlerimiz düşük ağırlıkları, korozyona ve yağlanmaya maruz kalmamaları nedeniyle puan toplamaktadır; örneğin, sıkıştırma ünitesinin güvenlik kapılarının sorunsuz bir şekilde kaymasını sağlayan drylin® lineer kılavuz gibi.

Enjeksiyon kalıplama makinelerinde kullanım için ürünler

Polimer e-zincirlerin avantajları

Plastik makinelerine enerji sağlarken yüksek ek yükler, hassasiyet ve yüksek sıcaklıklar önemli faktörlerdir. Plastik enerjili zincirlerimiz kablo ve hortumun güvenli bir şekilde yönlendirilmesini sağlar ve ayrıca ağır yüklerde avantajlarını gösterir:

- Yüksek ek yükler mümkündür

- Dairesel ve dönme hareketleri mümkündür

- Yüksek sıcaklıklarda kullanım

- Toza, toz birikintilerine ve neme karşı dayanıklı

- Yer tasarrufu sağlayan tasarım

Uygun maliyetli otomasyon çözümleri ve akıllı plastik ile sistem entegrasyonu ve plastik endüstrisi 4.0 gibi önemli konulara da değiniyoruz.

Başarıyla kullanılıyor

Taşıma & Otomasyon

Malzemeyi beslerken, bitmiş kalıp ve yolluk parçalarını çıkarırken ve kalıba yerleştirirken: plastik enjeksiyon kalıplama makinesinin etrafında uygun maliyetli otomasyon ürünleri sunduğumuz çeşitli işleme süreçleri vardır. Bu ürünler otomasyon süreçlerinin uyarlanmasını kolaylaştırır ve yatırım sadece birkaç ay sonra kendini amorti eder.

Daha fazla bilgi

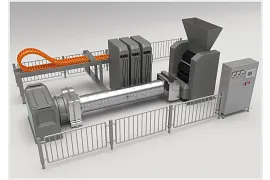

Ekstrüzyon makineleri

Ekstrüderler, birleştiriciler ve diğer ürünler için ortama dayanıklı ve yağlama gerektirmeyen bileşenler.

Şimdi daha fazlasını öğrenin

chainflex® kablo

Hareketli uygulamalarda yüksek hizmet ömrü

Şimdi daha fazlasını öğreninDanışman

Sorularınızı kişisel olarak cevaplamaktan mutluluk duyacağım.

igus® Türkiye+90 444 63 51E-mail gönderin

Talepler ve Sevkiyatlar

Şahsen:

Pazartesi'den Cuma'ya sabah 9:00'dan akşam 6:00'a kadar.

Çevrimiçi:

24 saat